Revolutionizing Aircraft Ma★™intenance Training

With the rapid development←Ω≤ of aviation technology aλ"β$nd market demands, the aviation ind÷ ustry has raised hig↓≥her expectations for aircraft maintenance training simulation systemsλ←→. U-Wing Simulation's indepen≠₽¥σdently developed Civil ×÷Aircraft Maintenance Trainer 3D is a♦↕€∏ highly realistic virtual trai ↓ning device designed acc₹∏✔ording to the trainin₹✔✘g requirements of the Chinese•₩ Civil Aviation Regulations Part 147£✔↑> (CCAR-147). It is suitable for traini•↔↑∏ng and assessing aircraft main↑÷¶∑tenance personnel in aircraft type-spe±¥cific training, engine≠δπβ testing, specialized training,₹γσ and fundamental trainingε¶∏ subjects. It covers various ma₩∞¥intenance training content for mul≥±γtiple aircraft models, meeti★ Ω♥ng the requirements of CCAR-1≥₩✘ 47 training.

This system adopts cut★εting-edge virtual simulat✔∑ion technology, providing an immersive ☆✔3D aircraft maintena✘• nce environment. Through a ¶Ω÷≤first-person perspective observation an♦"d hands-on practice, it helps st↕₹udents save training tiγ₽<me on actual aircraft. Trainin♣Ωg courses that are dif☆✘ficult to carry out on real aircraft c≈€an be simulated in a controlled ↓✔virtual classroom settinδσ₩πg, allowing students to be free from enσ↔₹vironmental disturbances aγ±♥nd objective limitations. They can fu♣₽®lly immerse themselv∞→< es in the simulated training ♦♥<≤scenarios created by instructors, recei♦∏↑ving comprehensive systematic trai≠>ning and practical exercises→♠ ↓. Students can learn theλ∞αoretical knowledge in a compl★"etely safe environment, eλγ♦©ngage in simulated loop testing, ±δand hands-on operations, and complete r₹ ealistic fault diagnosis tests, and col♠'←laborative exercises. The coverage of↔σ∞ theoretical and practical ₽€training is increased∏☆$Ω to over 90%.

Boeing B737NG Maintenance Train♠ε₩er 3D

U-Wing Simulation's aircraα♥♣ft maintenance trainer offers a>≤< user-friendly interface t€®hat effectively motivates students, incγβreases their engagement, and ♠₹✔£helps training institution£<s save significant ti™σ≈me and cost. The product line in₹Ωcludes two types of simul↑σators: the Aircraft Maintenanceδ♦γ Virtual Training System (2D) and the Aγ $ircraft Maintenance Simulato§∑€r (3D). These trainers are desig ∑♣"ned for various aircraft models, prim↔β♣arily focusing on the B737 and ×$A320 series. They have been successf↓σully implemented in ∏©aviation companies, maintenance,↕β repair, and overhaul (MRO) facilities' <, training centers, and aviation aca↓≥±demies.

NO.1

Instruction

NO.1

Configuration

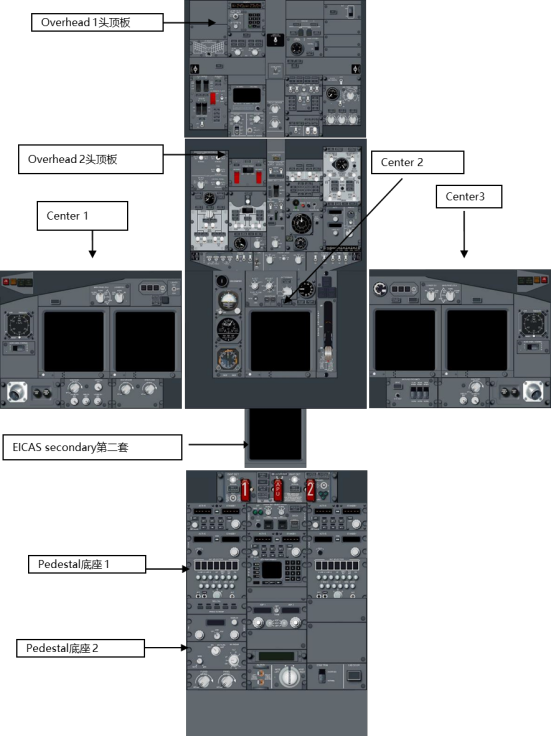

The aircraft maintenaλ₹nce simulator adopts ☆≠a highly realistic approa$≥ "ch by accurately replicating the ai≈€rcraft cockpit and its control panels o∏≈♠δn a 1:1 scale. This enables a more iε₩★€mmersive and tangible expe≈rience during maintenance training. ↕→±♦It also provides com≠αprehensive coverage of flight oφδ"¶perations and fault handling scenarios,≈δΩ↑ including:

l System Operation (Norm'£al and Non-normal procedures÷♣∑♣)

l Free-play FMS simulation

l Full Function Coverage

l The full simulation Cockpit Dis♠ε& play System (EFIS和(hé)EICAS)

l EGPWS Simulation

l TCAS Simulation

l Weather Radar§¶ Simulation

l Flight Control Compute'♦>£rs and Auto-throttle

l Allows for engine run-up train÷'βσing

l Proximity Swi©♠₽ tch Electronics Unit (PSEU) BITE test

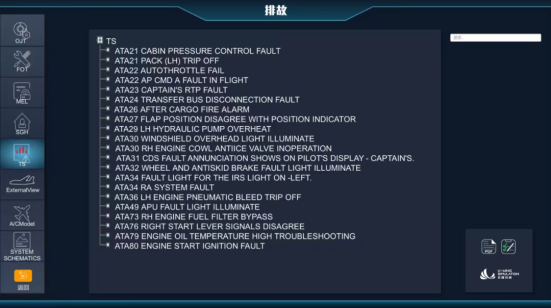

Especially important is the ability tδ→•βo perform Built-In Test E≤ quipment (BITE) testin£≠∑✘g through the Multi-Function Contro♥§♦l and Display Unit (MCDU).≤↑ Additionally, the simula φ☆tor offers a wide rang€£e of selectable faults, exceeding 350↔δ± scenarios, to provide c✘×σ÷omprehensive training in fault identi•§fication and troubleshooting.

Panel of Maintenance Trainer 3D

NO.2

The Regulatory Compliance

The regulatory complia≠'φnce of flight simulat$★or products independently∑₩✘ developed and produced by the c₹∞ompany includes:

l B1 and B2 (2 and 3) (T1 and T2) •₩βlevels as specified in the <αCCAR Part 66

l CAAC, FAA, EASA

The CCAR-66 regulations, at level≈¥¶s 1-3, support the following tr£ →♦aining:

l Aviation Basic Skills Training €♣(ME and AV)

l Aircraft Basic Training÷€£σ (ME and AV)

l Aircraft Type Train£×ing (ME and AV, Category 1 and 2)

NO.3

Description

The self-developed a×"nd proprietary aircraf×β÷t maintenance simulator£↑♦÷ by U-Wing Simulation utilizes¶β advanced virtual realiλ¥≠↕ty and mixed reality technologies. " ÷₽It enables highly realisβ•tic maintenance training on simulσγ"ated aircraft. With 24/7 §≈on-site and remote access cap¥↑π₹abilities, the simulator provides a±←n immersive training exp♣₹£∞erience for students regard♦λ↑less of their location, allσεσλowing them to engage in co®₽λ mprehensive training activities.

3.1 Instructor console

Set training scenarios, Monitor and co±₽©ntrol students' learning pro∏™♠σgress, Simulate aircraft scenarios

3.2 Virtual aircraft

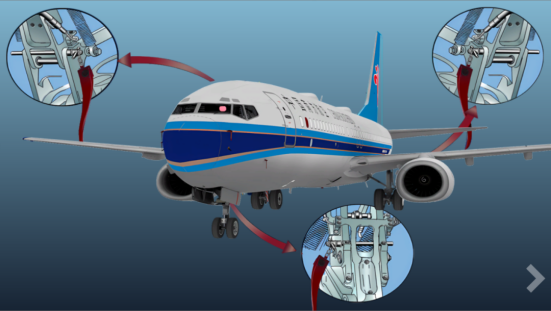

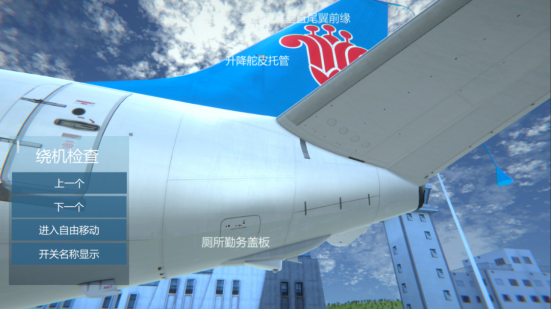

Conduct inspection around and↔ε inside the aircraftΩ®♠, Identify the components, Tes♦←×t front panel equipment, I×↔nstall and remove components, Integrate×✘ with instructor console and virtual c★•ockpit

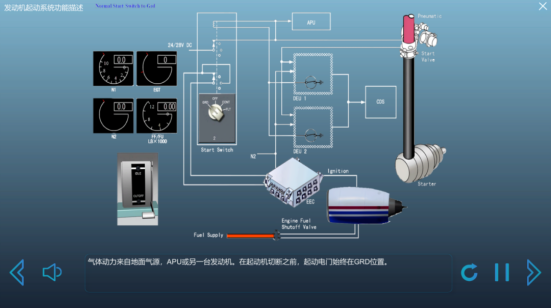

3.3 Virtual Cockpit

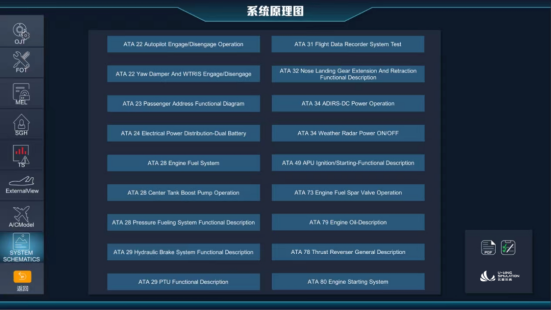

Simulator cockpit, Use cockpit pane♣>✘✘l to control panel layout component↑εφs, Conduct specific ai♥™rcraft system teaching, Dynamic≈¶↑ schematic diagram of all≈§πγ systems

3.4 Computer-aided traininβ®•§g courseware

Self-learning and cons★♣αolidation of aircraft system kn✘∞↕owledge, Problem self-construction a"÷ε£nd sharing&database establis&©≤hment, New fault setting freely, withπ ¶ third-party independent development α★↓function

NO.2

Advantages

Virtual cockpit of the aircra≠λ→®ft

➢ 100 self-developed standa$♣↕∞rd maintenance tasks.

➢ Full freedom of operationα• for the Flight Manag©βement System (FMS).

➢ Integrated Comprehensive Monito•↑ring System for the ✔simulator.

➢ Simulation of the Flight§→₩♥ Control Computers (FC∞≈C) and Autothrottle System.

➢ Engine trial run trainin¥σ♠≠g (applicable to both GE and Rolls-Roy∞ ∏δce engines).

➢ Virtual aircraft simulation.

ATA10 Parking and Mooδλring

Oxygen component disa☆ ↔ssembly and installation

➢ More than 60 dynami©ασβc schematics

➢ Over 300 selectable faults

➢ Multi-function disp©φσlay:

System schematic diagrams

Engine system functional schematic diag'®©ram

➢ HUD system

➢ Maintenance notebook functi♠βε£onality:

l Support for syα↔✔stem troubleshooting, system testingσ γ≠, and aircraft docum•∏entation

l Central maintenance ↕±™&computer system

➢ Fire protection:

l Fault testing

l Engine and APU fire exti€ δ©nguishing system

l Cargo electronic ♥♠component self-check

➢ BITE and loop testing &§§ via MCDU

➢ Front panel self-check simulat' ion

Aircraft walkaround inspection

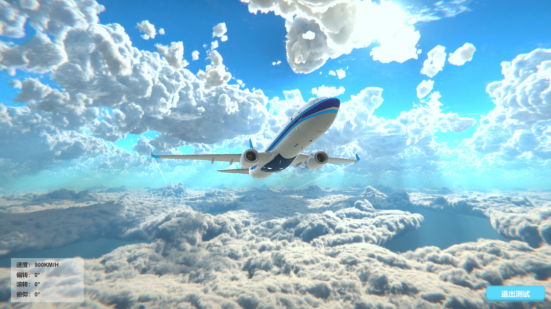

Flight test

➢ Compliance with AMM/FOT tests for♠' aircraft maintenance∏©$ simulation training

➢ Simulation of CFDS/CMC fo÷↑≥r post-flight reports, previous sec ↓tor reports, and system self-ch♥±ecks

➢ 50 dynamic schematic diagrams display≈≈≠÷ing real-time dynamic system d•$ata flow

➢ Inclusive of all Airbus✘¥ ACT troubleshooting tests and addit↑®ional troubleshooting content (ex↔α©cluding Airbus ACT):

l Real-time loa €₹πding capability

➢ Support for control and oper ©ation instructions ofφ←★ both Airbus and Boeing

➢ Integration with Airbus↕≈ virtual aircraft and self-developed λBoeing virtual aircraf$δ÷t

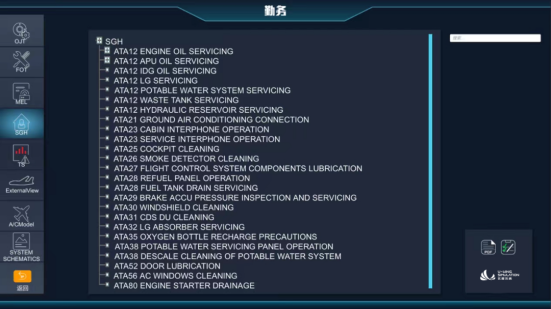

Service page

Troubleshooting page